| 4柱无线重卡举升机 TF-4055/TF-4075 | ||

| 参数/型号Specifications/Models | TF-4055 | TF-4075 |

| 柱子数量Column quantity | 4 | 4 |

| 单柱举升重量Lifting weight per column | 5.5T/5500kg/12000lbs | 7.5T/7500kg/16500lbs |

| 总举升重量Total lifting capacity | 22T/22000kg/48000lbs | 30T/30000kg/66000lbs |

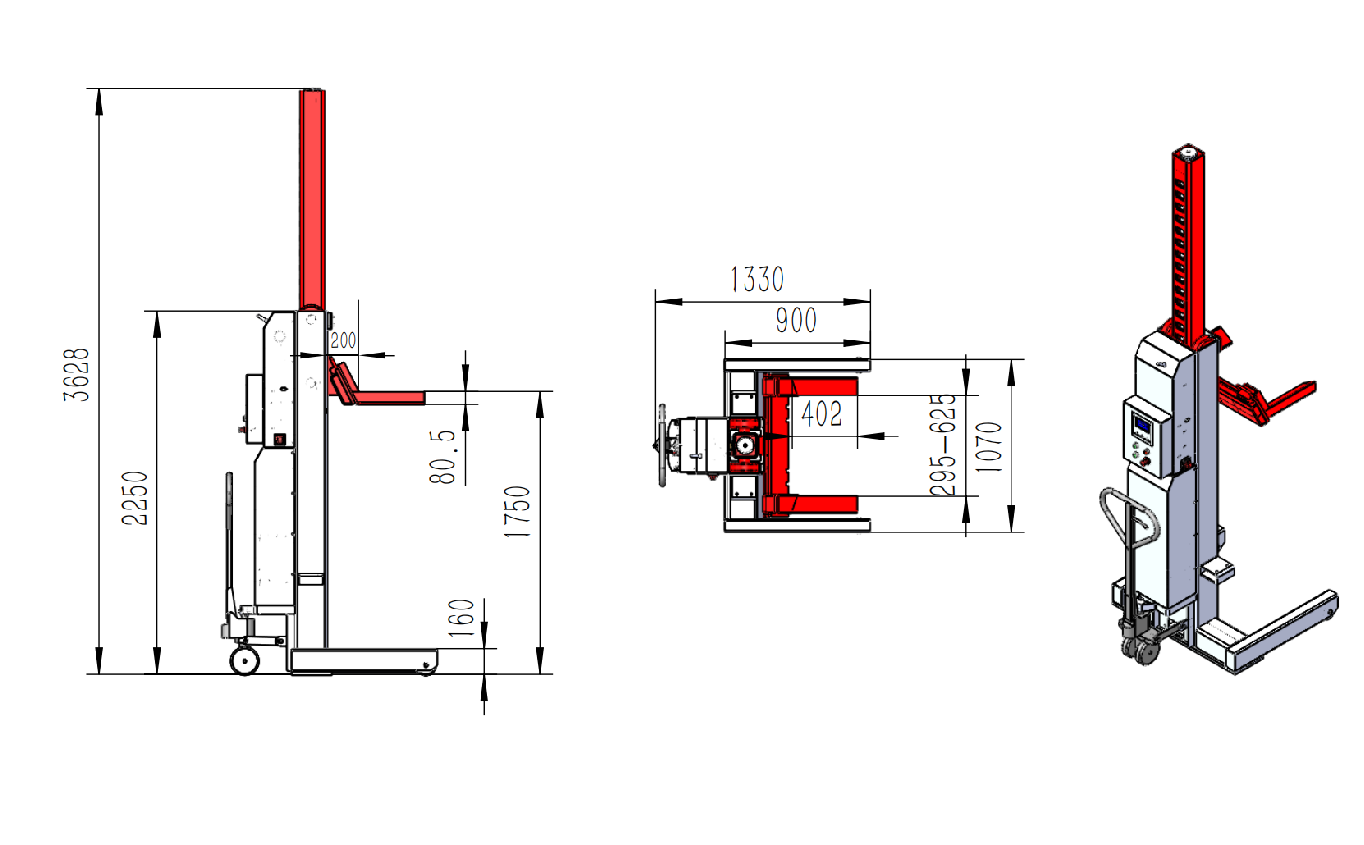

| 举升高度Lifting height | 1750mm | 1750mm |

| 使用轮胎直径Applicable tire diameter | 500mm-1120mm | 500mm-1120mm |

| 叉臂长度Fork length | 402mm | 402mm |

| 上升/下降时间Lifting time/Falling time | 75s/110s | 75s/110s |

| 工作电压Working voltage | DC24v | DC24v |

| 充电电压Charging voltage | 110v-240v | 110v-240v |

| 单柱功率Motor power per column | 3kw | 3kw |

| 柱子尺寸Column size(L*W*H) | 1330mm*1100mm*2250mm | 1330mm*1100mm*2250mm |

| 柱子重量Column weight | 630kg | 680kg |

| 移动式三角支架Mobile axle stands | 选配Optional | 选配Optional |

TFAUTENF重卡举升机是一种专门用于汽车维修保养的设备,主要用于举升比较大的重型卡车。它可以通过液压系统将重型卡车抬升至一定高度,便于对其进行车底维修、更换轮胎、更换液压油等操作。重卡举升机需要具备强大的承重能力和稳定性,以确保安全和可靠性。此外,它还需具备可移动性,以方便在不同位置使用。举升机还可以用于举升货物,生产线配套、物流码头等,前提必须确保货物的钢性强不折弯。高科技的自主生产线和国际化的组织团队使其成为重卡举升机领域的佼佼者,备受重卡汽保商、公交车维修服务站、装载车厂等领域青睐!我们严格按照欧洲标准 EN1493: 2010 要求进行设计制造。

产品优势:

A.我公司自主研发的电控系统,采用美国ZigBee无线通信技术,更为高效、便捷的特征,信号稳定性强,抗干扰能力强,同时配有冗余备份系统,一旦受到其他干扰源干扰,备份系统启动工作,不影响设备正常运转。

B.设备采用闭环控制原理,可进行单柱,双柱或多柱选择操作,采用微电脑处理器实时控制,实现高精度同步,设备每个柱子都配有液晶显示屏,实时显示升降高度,电池电量,以及设备故障报警码。

C.设备符合人机工程学原理,每个柱子均有独立操控系统,可延伸连接六柱.开机自动选择最佳信号连接,无需人工干预。

D.设备在安全承载状态下,具有机械/液压双重锁止功能,自动过载保护,最高最低点时自动停机,下降过程中,距离最低点33CM时,蜂鸣器报警,提醒操作人员检查有没有障碍物影响设备运行。

E.每个柱子上均设有独立的电源开关以及紧急停止开关,一旦有紧急情况,能够第一时间断电。

F.设备在运行过程中,高度差达到15mm时,微电脑自动调整平衡。严重超差(≥50mm)或由于某根立柱上电源掉电不能升降,设备自动停机。产品有液晶显示柱子的高度、模式、状态,具有自诊断功能,能够显示故障状态。

G.为了使设备移动方便,每个柱子都有液压小车,可人工拖动,同时配有供叉车叉举使用的防反转叉车支架。

H.充电设备采用台湾公司生产的大功率充电器。性能稳定,充电效率高。

Product advantages:

A. The electronic control system independently developed by our company adopts the American ZigBee wireless communication technology, which is more efficient and convenient, has strong signal stability and anti-interference ability, and is equipped with redundant backup system. Once interfered by other interference sources, the backup system starts to work and does not affect the normal operation of the equipment.

B. Adopt closed-loop control principle: single column, double column or multi-column selection operation can be carried out. Real-time control by microcomputer processor is adopted to realize high-precision synchronization. The displacement sensor is used to detect the height of the equipment in real time.

C. Human Engineering: Each column is equipped with an independent control system and hydraulic power unit, which can be extended to connect six or eight columns.

D. Safety measures: When the equipment is in a safe loading state, it has a mechanical/hydraulic double locking function, automatic overload protection, which automatically stops at the highest and lowest point. When carriages descend to 330 mm off ground, they will stop automatically, and warning alarm rings to remind operator not to put feet under carriages.

E. Each column is equipped with an independent power switch, emergency stop switch, once there is an emergency, can be the first time off.

F. Diagnosing trouble function: During the operation of the equipment, when the height difference reaches 15mm, the microcomputer automatically adjusts the balance. If it is seriously out of tolerance (≥50mm) or cannot be lifted due to power failure on a certain column, the equipment will automatically stop. The product has a LCD screen display column height, mode, status, has a self-diagnosis function, and can display fault status.

G. In order to facilitate the movement of the equipment, each column has a hydraulic trolley, which can be manually dragged, and is equipped with an anti-reverse forklift bracket for forklift fork lifting.

H. The charging equipment adopts the high-power charger produced in Taiwan. Stable performance, high charging efficiency.

我们会在第一时间与您联系.